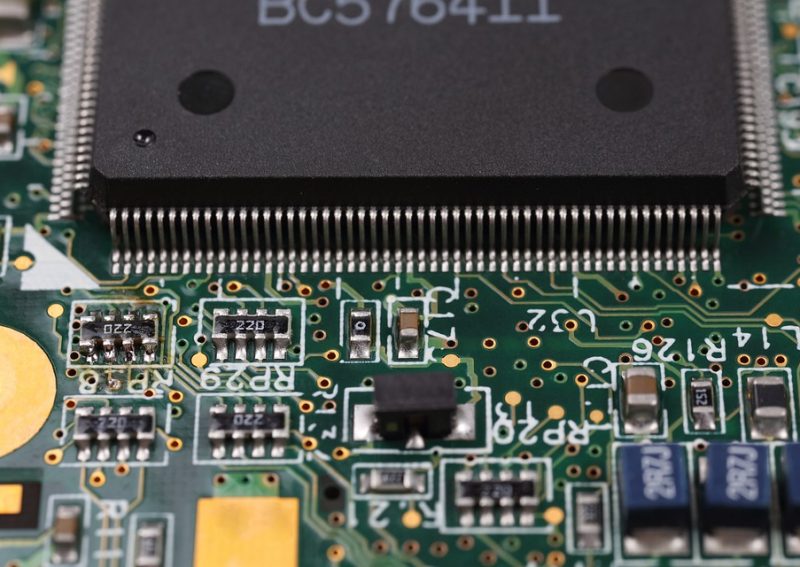

Turnkey PCB Assembly Services are the solutions utilized to manufacture a single electronic contract using the PCB board. Almost All modern time technologies depend on PCB; cell phones, radio, digital cameras, and cell phones have these boards in their devices to perform electronic functions. For PCB to perform well, it should have all the components aligned correctly.

The manufacturing companies employ turnkey Assembling services to handle all the tasks related to PCB projects. The company finds out the sources, components, joints, and parts required for PCB design. The assembly department focuses more on designing and manufacturing the printed circuit boards that create the perfect PCB structure.

Methods of Turnkey PCB assembly

Turnkey PCB manufacturers undertake the contract of making a specific model and design of the circuit board following a particular electronic agreement. Once they sign the deal, their job is sourcing, designing, testing, inspecting, finding components, and assembling the PCB according to the terms stipulated in the document.

Employees of the assembly department are responsible for purchasing the components needed for the boards. Moreover, they are accountable for the quality of all the significant features and parts used for the board.

At the initial stages, the R & D team takes the responsibility of designing and developing the functional PCB board regardless of the volume. QC team sets the standards, design terms, rules, and regulations that the production department follows. All the tools are shipped to the production and manufacturing team for preparing the designs of specific models of PCB.

The manufacturing team arranges the parts in the right order for the assembly process. They solder the components on PCB boards when all the necessary tools, parts, and components are made available at their disposal.

For the Turnkey PCB Assembly Services, the automatic assembly units and electronic machines are used for soldering the components on electronic boards. Once the process is completed, the QC team performs the test to analyze if the circuit boards meet the team’s design terms. Once a final product is manufactured, the employees make arrangements for the packaging and start shipping.

Benefits of using Turnkey PCB assembly

Turnkey PCB assembly is cost-efficient, quick, and proactive. It helps develop and build impeccable design for a prototype faster through proper planning. So, this enables the vendor to get the electronic board assembly done more quickly than usual. The single point of contact initiates the assembly process, and the products are ready to reach the market immediately.